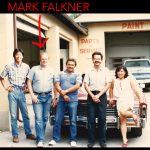

Although Dennis Wood seems to be the mustache err face of TeraFlex, the off-road Jeep performance equipment company is owned by Mark Falkner. Today, we would like to spotlight Mark on his birthday.

Born April 3, 1957, Mark Falkner enjoys spending time with his family, his work, and his church. He is fortunate to work with many of his children and their spouses here at TeraFlex.

Mark enjoys a good donut, Diet Coke, and anything with chocolate. Although he has his favorites, he is also willing to try new foods without complaint. He loves teaching — and teasing — his grandkids. His treasured gifts always touch his heart or bring a good laugh.

Happy Birthday, Mark!

Like many here at TeraFlex, Mark has been around the Jeeping industry a very long time, and we think people deserve to know more about the Jeep suspensions expert behind the brand!

BRIEF BIO:

- 1957: Born in Salt Lake City, UT, and grew up in a family of 10 kids.

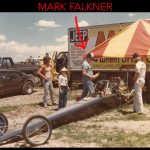

- 1959: Father started company MEPCO (Military Equipment Parts Company) which bought and sold Jeep/Truck-related military surplus.

- 1966: (Age 9) Started working on and off at MEPCO.

- 1971-72: (Age 14-15) Worked at Jeep Joint in Murray, UT repairing and restoring Jeeps part-time in the evenings.

- 1982: Left MEPCO to work as a manager at a Chevrolet service department.

- 1986: Bought MEPCO from his father who retired and became the new owner of MEPCO.

- 1996: TJ Wrangler came out, opening an immediate demand for a TJ Wrangler lift kit which did not yet exist. Mark Falkner developed the first TJ Lift Kit in the world and started the brand-new company TeraFlex Suspensions, which would focus solely on the development and manufacturing of parts and suspensions for the Jeep Wrangler.

- Today: Still here as acting President of TeraFlex.

We asked Mark to tell us about his life experience coming into the Jeep industry and the eventual development of TeraFlex. Here is Mark Falkner's remarkable story:

We asked Mark to tell us about his life experience coming into the Jeep industry and the eventual development of TeraFlex. Here is Mark Falkner's remarkable story:

“My earliest memories are from the 1960s when I was working as a youngster in the yard. Those days I would sort through the military surplus we had purchased by auction at the different military bases. I collected 5,000 first and reverse shift forks for a T84 tranny, 140,000 MB mufflers, and so on.

“Once we had a good count, we would call the other guys in different parts of the country and trade them for some of the cool parts that they would get. After a lot of negotiating, we would have enough variety to fix those old army Jeeps with just about any part they needed. Many of the big players in the industry today had their roots in the military surplus business from the 60s. My brother and I built our Jeep projects from the surplus parts we had around the yard. Everyone that had an old Jeep wanted more power, so we manufactured our own adapter plates to bolt up GM and Ford engines to the old 3-speed trannies. We had a lot of fun with the early off-road rallies and races. M38A1 Army Jeep + 327ci Corvette engine = more fun whether it was in the snow rally or in the dirt. I learned a lot from those race days and engine swap successes and failures.

“In the 70s, the Jeep engines got bigger, so we sold more lift kits along with the repair parts for the Jeeps. Chrome add-on bits and tube bumpers became the must-have accessories of the day. Roll bars were not standard equipment until 1976 and so we would bring a truckload of roll bars every other month from the Smitty Brothers in Southern California. I don’t know how many roll bars we sold for Broncos, Blazers, and the Jeep CJs, but it was in the thousands. Another thing we did a lot of in the 70s was putting four-wheel-drive in the new import trucks. Toyota, Datsun, and the Chevy Luv trucks became very popular with the gas embargo situation in 1974, but they didn’t offer 4x4 versions. So, we made conversion kits and did a lot of the upgrades for the dealers.

“The 80s brought some concerns with the engine conversion business because of the new emission control laws, but it didn’t take us long to sort that out. Stainless accessories replaced chrome and the new square headlamp YJ Wrangler hit the market in 1987. The mostly functional windshield wipers and defrost improved the quality of life by leaps and bounds. I had a 1979 Golden Eagle edition CJ7 that I bolted up some YJ fenders and a grille and hood that inspired a fair number of customers to do the same. In the 60s and early 70s, the Muncie 4-speed transmissions became a popular swap because they could handle the bigger V-8 engines but they often had close-ratio gears that caused problems for driving in places like Moab. The T18 Truck transmissions and GMs SM420 gearboxes became popular because of the 6:1 and 7:1 granny gears.

“The 80s brought some concerns with the engine conversion business because of the new emission control laws, but it didn’t take us long to sort that out. Stainless accessories replaced chrome and the new square headlamp YJ Wrangler hit the market in 1987. The mostly functional windshield wipers and defrost improved the quality of life by leaps and bounds. I had a 1979 Golden Eagle edition CJ7 that I bolted up some YJ fenders and a grille and hood that inspired a fair number of customers to do the same. In the 60s and early 70s, the Muncie 4-speed transmissions became a popular swap because they could handle the bigger V-8 engines but they often had close-ratio gears that caused problems for driving in places like Moab. The T18 Truck transmissions and GMs SM420 gearboxes became popular because of the 6:1 and 7:1 granny gears.

“In 1996, we made a suspension kit for the first TJ Wrangler we could get our hands on. We made it work the way we thought it should in Moab and on the highway. We liked it and so did our customers. To this day, we applaud the new Jeeps and all the cool features and comforts, but we always look at making them better for our own type of off-road, on-road use.”

Mark says much of his motivation for Jeeps came from his older brother Lynn.

“My older brother Lynn raced our company Jeep in the late 60s and early 70s, where I helped as pit crew. It was fun and exciting. Jeeps were the family business, so it was just something we did.”

Mark lives in Salt Lake City. He is happily married to Sid Falkner and a proud father and grandfather of many Jeepers — several of who work at TeraFlex. Yep, we're a family company!